Lamination techniques with high strength copper alloy sheets 50 μm thickness or stainless steel ss sheets 20 μm thickness for both sides of bare bi 2223 wire gave approximately 300 mpa tensile stress tolerance and 0 4 0 5 tensile strain tolerance which was defined to retain 95 critical current compared with those of nonloaded.

Astm steel sheet inspection lamination.

The method involves generation of homogeneous field parallel to sheet surface.

1 1 this specification 2 covers the procedure and acceptance standards for straight beam pulse echo ultrasonic examination of rolled fully killed carbon and alloy steel plates 1 2 in.

Fully processed magnetic lamination steel metric replaced by a840 a840m no materials a 841 a 841m.

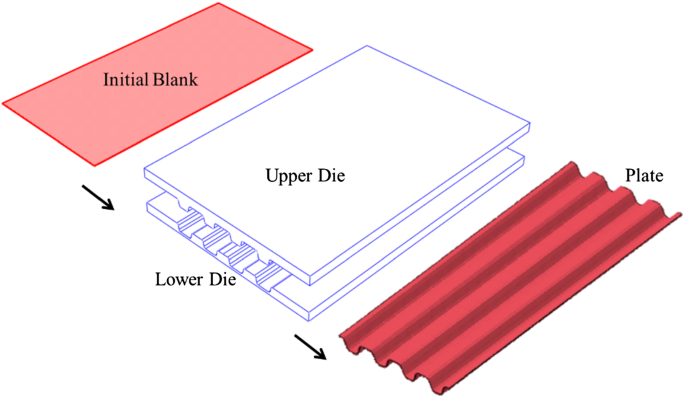

4 1 lamination factor s indicates the deficiency of effective steel volume which is due to the presence of oxides roughness insulating coatings and other conditions affecting the steel surface.

More detailed information about these two types of steels can be found in the metals handbook.

Electrical steel is usually manufactured in cold rolled strips less than 2 mm thick.

Astm s steel standards are instrumental in classifying evaluating and specifying the material chemical mechanical and metallurgical properties of the different types of steels which are primarily used in the production of mechanical components industrial parts and construction elements as well as other accessories related to them.

Electrical steel lamination steel silicon electrical steel silicon steel relay steel transformer steel is an iron alloy tailored to produce specific magnetic properties.

There are two types of electrical steels used for rotor laminations semi processed and fully processed.

12 5 mm and over in thickness.

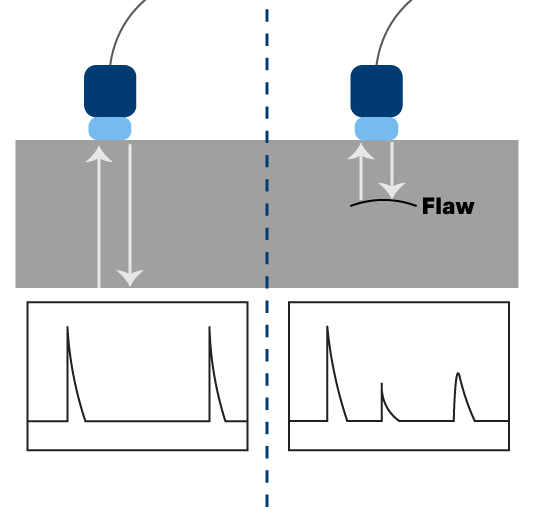

Magnetic flux will bend in the presence of inclusions or lamination beyond the surface of the sheet.

4 2 the term lamination factor s pertains strictly to the determination of the proportion of material as defined by precise sampling and.

Steel plates for pressure vessels produced by thermo mechanical control process tmcp 1 a 844 a 844m.

The magnetic particle inspection can measure the presence of inclusions larger than 30 µm in steel sheets.

Cold rolled motor lamination sheet is a special type of cold rolled steel sheet product that is produced to maximize the performance of the products for use as electro magnetic core materials for electrical equipment components.

The steels used for these applications are designed to.

1 1 this specification covers cold rolled carbon sheet steel used for magnetic applications.

These products commonly called cold rolled magnetic lamination steel crml are usually intended for applications in which the stamped laminations or assembled core structures for electrical equipment are annealed to develop the desired core loss and permeability characteristics.

It was developed to assure delivery of steel plates free of gross internal discontinuities such as pipe ruptures or laminations and is to be used whenever the inquiry.

Both are non oriented steel grades.